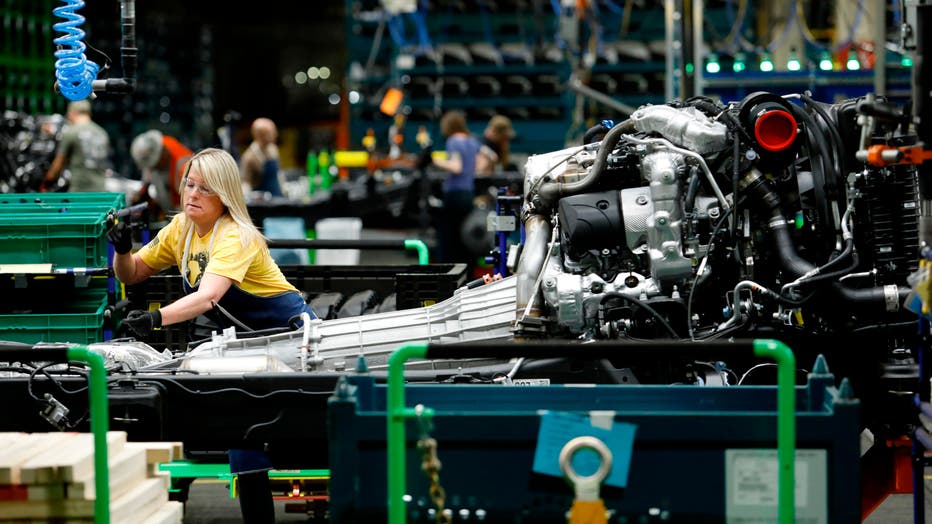

Auto suppliers go back to work as Michigan manufacturing begin restart amid COVID-19

SOUTHFIELD, MIch. - Before vehicles can start rolling off the lines, they need the parts to do it. May 11 represents the first link in that supply chain restarting.

On Monday, Michigan auto suppliers will return to work as they begin feeding the manufacturing sector amid the COVID-19 crisis. It's one of the governor's latest orders relaxing business in Michigan as it begins re-engaging its economy.

"You look at the suppliers, we have to produce parts, we have to ship it, get the logistics going. So there's us getting a headstart by a few days makes a huge difference to the success they'll have in their ramp-up," said one industry specialist.

That headstart will last about a week as Ford, General Motors, and Fiat-Chrysler have all announced plans to reopen their assembly plants on May 18 which will mark the conclusion of almost a two-month stretch since factories first shuttered.

As Gretchen Whitmer has slowly rebooted sectors of Michigan's economy, she's been in touch with many industry advocates over the weeks. That includes Glenn Stevens, an executive at MICHAuto, who wrote a letter on behalf of the Original Equipment Suppliers Association, who asked for the needed time to restart the auto-making supply chain.

"Well everything is driven by the auto manufacturers, the OEMs, and it's a very complex supply chain. Goes across states, goes across international boundaries, and so when OEM start, the pipeline has to be filled because about 70-75% of the components come from the suppliers," said Stevens.

So what will that restart look like? As Automation Alley President Tom Kelly puts it, it'll be "in a million different ways at a million different companies."

While manufacturers don't have to worry about transmission of a virus between customers and employees, their staffs do work in tight quarters that will require bending social distancing guidelines at times.

(Photo by JEFF KOWALSKY / AFP) (Photo credit should read JEFF KOWALSKY/AFP via Getty Images)

To combat the potential exposure, Detroit's big 3 among other companies will deploy safety precautions utilized in other factories up and running.

"This is a global industry so many of the companies just in our own backyard have been operating in China, Italy, and other places around the world so when you look at companies like Ford, GM, LEAR, Magna, Adient, they've all got very complex safety protocols, and so do all the other suppliers," Stevens said. "So they've been learning from them, getting ready for them, and this is a process that didn't start last week, it's been going on for some time."

The companies haven't just followed the example of other foreign factories, but some at home as well. Both GM and Ford have been using temperature screening and enhanced personal protective equipment at factories making essential supplies for front line workers. Paid volunteers from the UAW have been working for more than a month making ventilators, respirators, face shields, and gowns for health are workers.